QJET Operational Facilities Maintenance

QJET ensures regular maintenance of its Midfield and Western Fuel Farm operational facilities within Hamad International Airport (HIA) to uphold safety, reliability, and compliance with aviation industry standards.

QJET Operational Facilities Maintenance – Hamad International Airport (HIA)

QJET operates a robust fixed asset maintenance program within the premises of Hamad International Airport, covering critical fueling infrastructure at its two main operational facilities: The Midfield Fuel Farm (MFF) and Western Fuel Farm (WFF). The program encompasses maintenance of hydrant pits, underground piping, fuel pumps, filtration systems, valves, and associated storage facilities. This comprehensive approach ensures maximum reliability, operational safety, and regulatory compliance with international aviation fueling standards, including those prescribed by the Joint Inspection Group (JIG).

Scope of Fixed Assets Covered

• Hydrant pit assemblies, including valves, hoses, and couplings

• Underground hydrant piping and control valves

• Fuel filtration and water separation units

• Pumps and pumping skids

• Tank gauging and measurement Instruments

• Safety systems, including emergency shut offs and alarms

• Aboveground and underground storage tanks and associated equipment

• Fire suppression and spill containment systems

• Infrastructure and equipment at both Midfield Fuel Farm (MFF) and Western Fuel Farm (WFF) facilities

Maintenance Objectives

• Prevent unplanned downtime and operational disruptions across both fueling farms

• Ensure continuous fuel quality and flow integrity throughout all facilities

• Maintain compliance with IATA, JIG, ICAO, and QCAA regulations

• Protect personnel, aircraft, and the environment through reliable safety systems

• Facilitate audit readiness and support airline quality assurance requirements

Additional Compliance Measures

• Maintenance activities are meticulously logged, with digital records accessible for audits

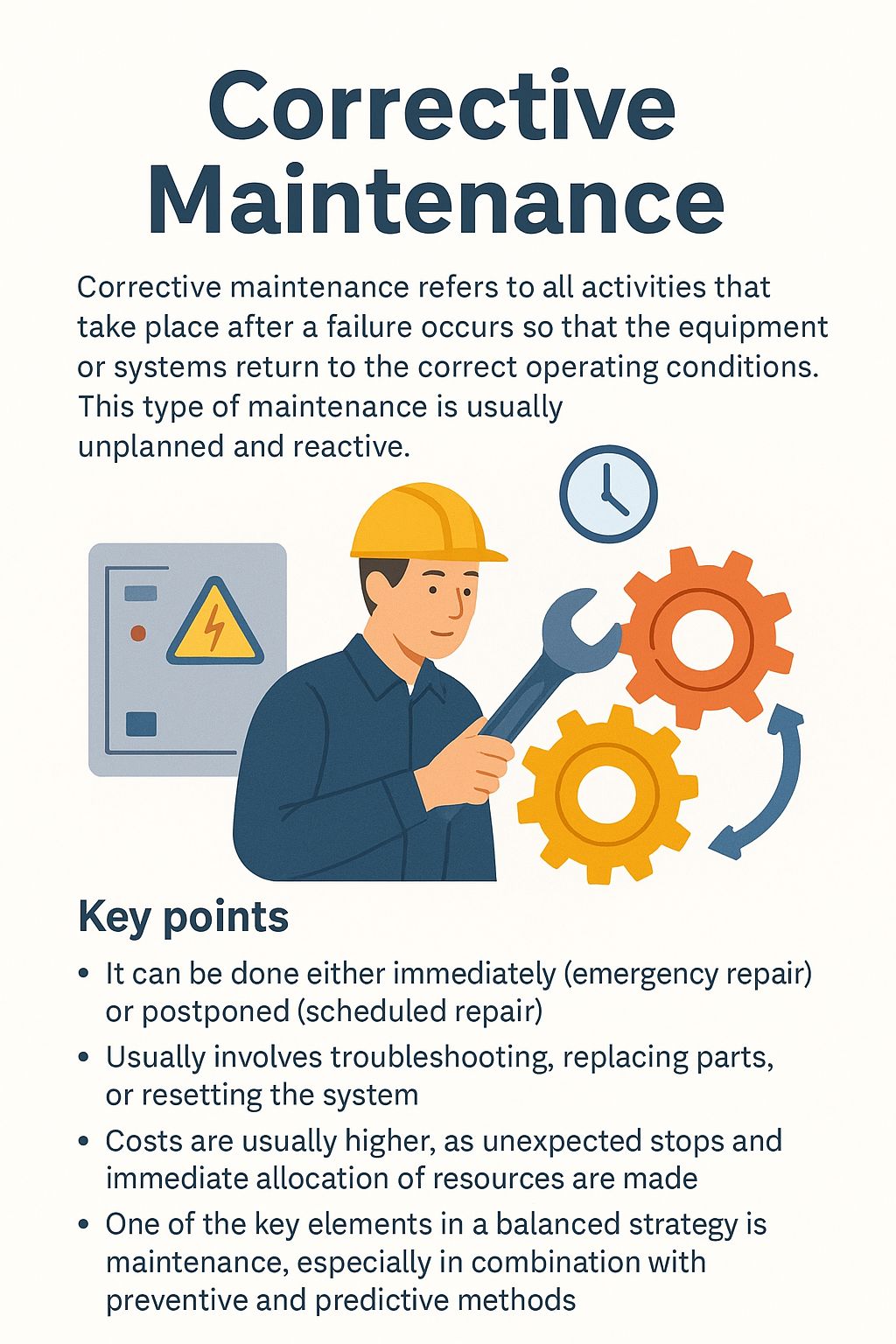

• Any deviations or faults trigger immediate corrective action and are reported to management

• Regular training ensures that maintenance personnel remain current with JIG competency requirements

• Close coordination with airport HSSE teams ensures safe maintenance practices within all operational zones

Benefits of QJET Fixed Asset Maintenance Program

• Enhanced system reliability reduces fueling delays and improves aircraft turnaround times

• Improved fuel quality assurance through well-maintained filtration and pumping systems

• Compliance with global aviation fueling standards builds trust with airline customers and regulators

• Proactive maintenance minimizes the risk of environmental incidents and operational hazards